Description

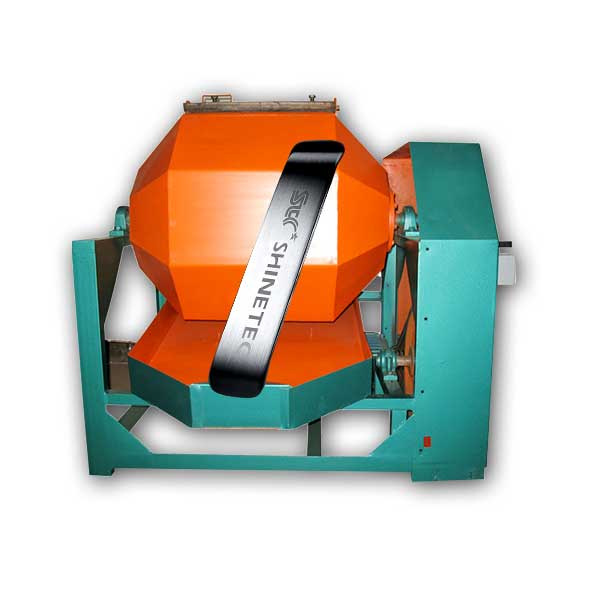

Tumbling Barrel Finishing and Polishing Machine

Tumbling barrel finishing machine, also called the rotary barrel tumbler, and the barrel automatic deburring machinery, are the oldest surface treatment models. Suitable for deburring, descaling, deflashing, chamfering and surface bright polishing of various parts of metal and non-metal products.

This machine uses the principle of centrifugal motion. The workpiece and abrasive media rotate up and down relatively slowly in the barrel. The abrasive media and the workpiece rub against each other to generate cutting force to achieve the purpose of finishing and polishing.

It is still widely used today because it is the cheapest to process.

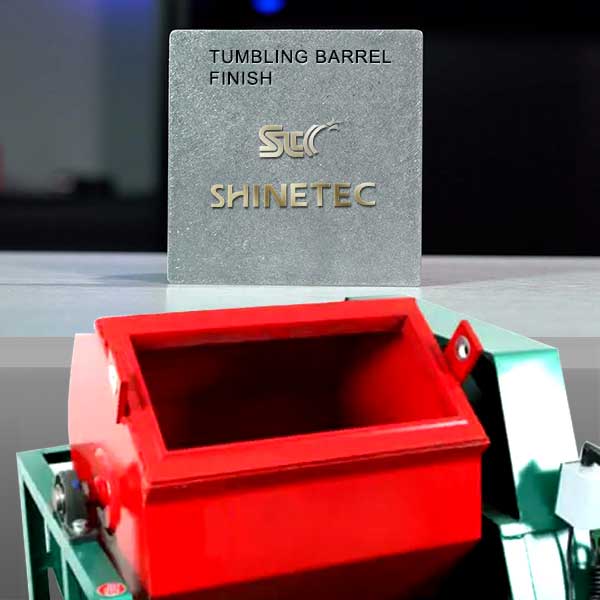

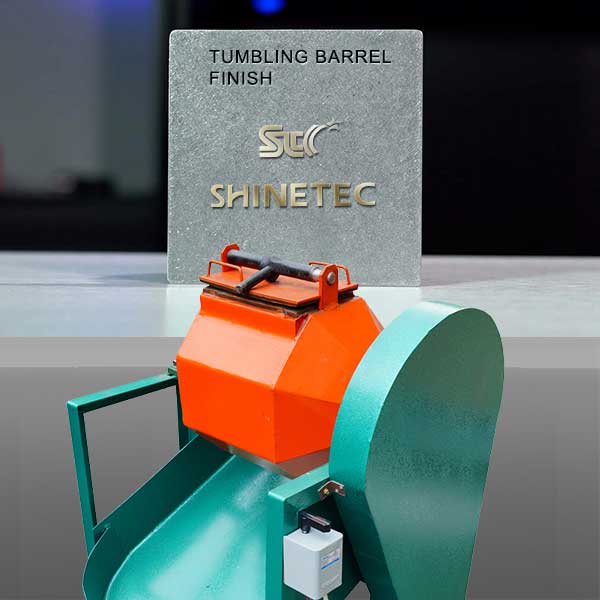

However, due to the slow rotation speed of the barrel, this polishing process usually takes several hours or even days, but the brightness of the surface after treatment is the best.

Compared with other mass finishing machines , the tumbling barrel polishing machine is characterized by slow work and meticulous work, with the lowest efficiency, but the highest surface brightness.

It is suitable for some workpiece that require high surface brightness. It can reduce the surface roughness of the parts by 1-2 levels and achieve a mirror polishing effect.

Optional:

1. Independent control box: facilitates safe operation of the equipment and prevents motor current overload.

2. Frequency converter: The frequency range is adjustable, and the speed of the barrel can be adjusted by adjusting the running speed of the machine motor.

3. The barrel can be lined with polyurethane material (PU) or wear-resistant natural rubber, which is acid, alkali and wear-resistant, and can prevent the workpiece from being damaged by direct contact with the iron plate of the barrel wall.

4. An optional safety protective cover is available outside the barrel to improve the operating safety of the machine.